APPLICATION

LED Sealing Material

Problems

- check_boxIt is difficult to mix powders such as phosphors and dispersants uniformly.

- check_boxThe materials are expensive, but improving the yield is difficult.

- check_boxMixing and defoaming process is time-consuming.

Solution

- check_boxHigh shear force enables uniform defoaming and improved performance (brightness).

- check_boxThe yield rate can be improved by non-contact manner.

- check_boxDefoaming can be done simultaneously with mixing, which shortens the processing time.

Test Result

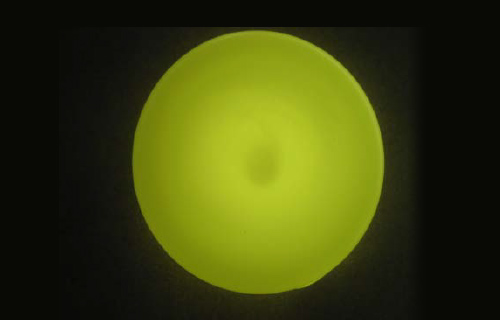

Uniform mixing when the revolution speed is set at 1:1.

There is a few phosphor precipitates.

No phosphor precipitates.

Recommended models

2 axis 350g×2 cups

2 axis 1kg×2 cups

Independently variable revolution/rotation speed (2 axis)

Independently variable revolution and rotational ratio are advantageous for mixing materials with large differences in specific gravity, such as silicone resin/epoxy resin and phosphor.

Vacuum model

Prevents degradation in quality due to fine bubbles.