Wire Harness Manufacturing

Automatic Lead Wire Soldering

Robot package

Three feature of manufacturing/Automation robot packages

-

01

Robot movement takes about 5 seconds

We automate robot operations at a speed of 5 seconds + "wire harness manufacturing," "terminal crimping," "soldering," etc.

-

02

Compatible with a wide variety of products

Unlike dedicated equipment, we use robots, so one system can handle a wide variety of products.

-

03

Flexible customization to suit your needs

It can be customized to suit a wide variety of manufacturing processes, such as crimping terminals to the tips of wires, inserting terminals into connectors, and soldering.

-

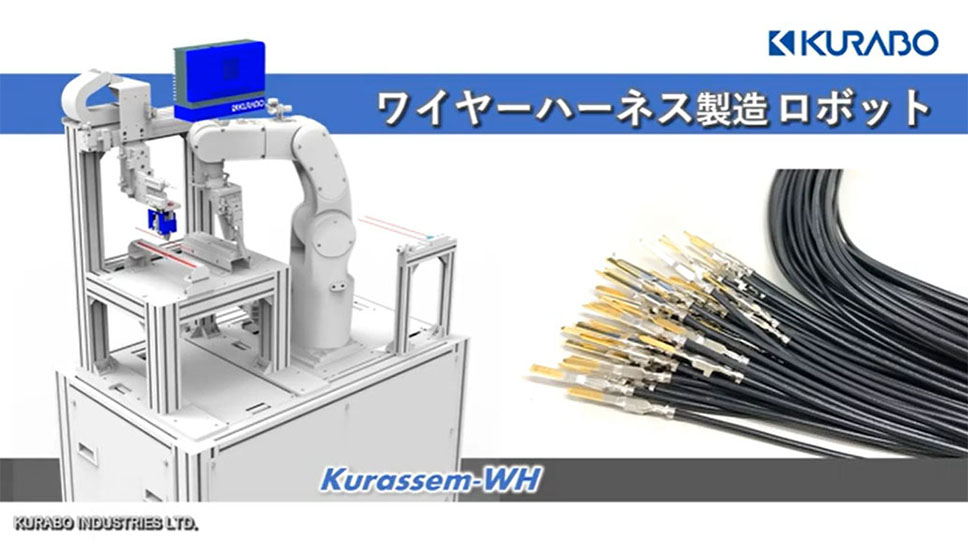

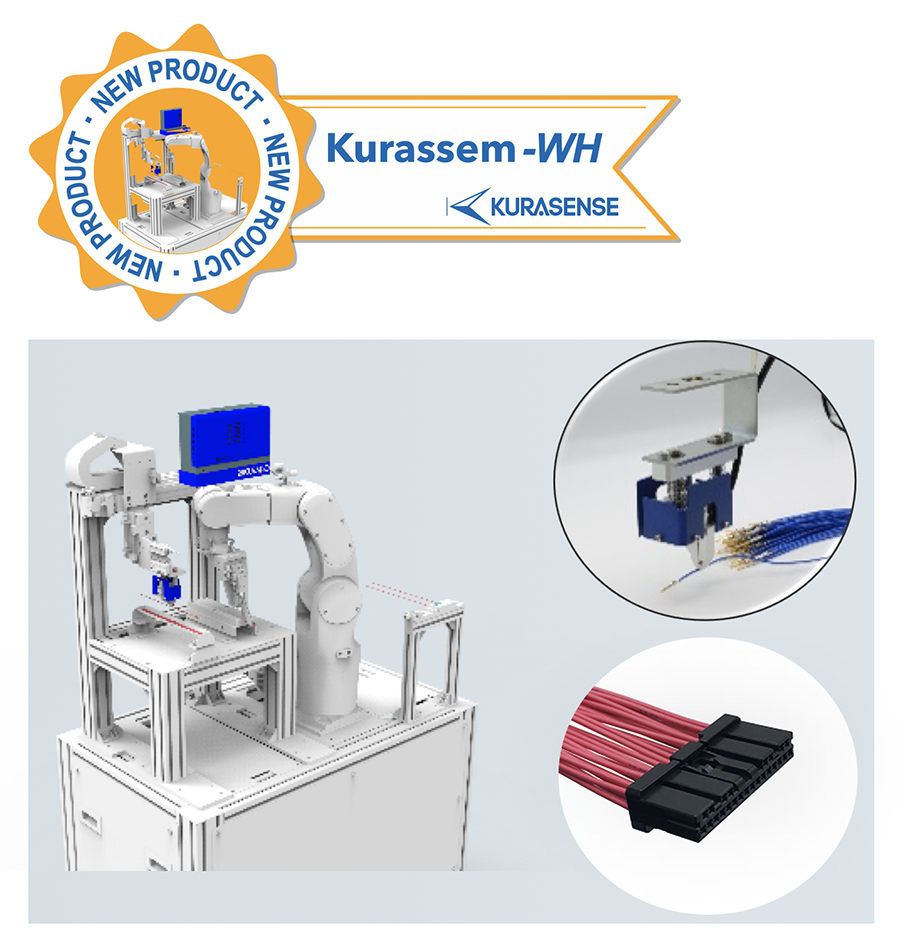

Wire Harness Manufacturing Robot Kurassem- WH Kurassem-WH

It takes about 10 seconds to take out one wire from a bundle of wires, crimp the terminal, and insert it into the connector.

We can customize soldering, characteristic testing, etc. according to customer requests.

Wire Harness Manufacturing Robot Package

Wire Harness Manufacturing Robot Package

Kurassem-WH

Can be customized according to applications such as terminal crimping, soldering, and characteristic testing.

This is a robot package that takes out one cable from a bundle and processes it to target work in about 5 seconds. It is possible to customize a predetermined position to a "terminal crimping machine, soldering machine, etc." according to your request.

- Compatible work

-

- Diameter

- Φ0.5 ~ 2.0 mm

- length

- 100-300 mm

- Number of inputs

- 1000 pieces

*Please contact us separately regarding the workpiece diameter and number of inputs.

- Robot

- Robot specified by your company

- 3D sensor

- Made by Kurabo Kurasense - C100FX

- Work supply

- Kurabotte made by Kurabo - P150

- Equipment size

- 900(W) x 1200(D) x 1800(H) mm

- Utility

-

- power supply

- 3 phase AC200V 30A 50Hz/60Hz

- air

- 0.4 MPa

- Target work

-

- Terminal crimping, connector insertion, soldering, resistance welding,

- Characteristics tests, appearance inspections, etc.

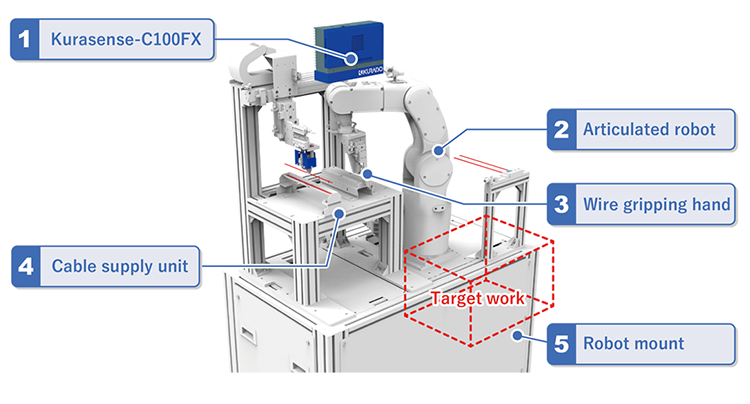

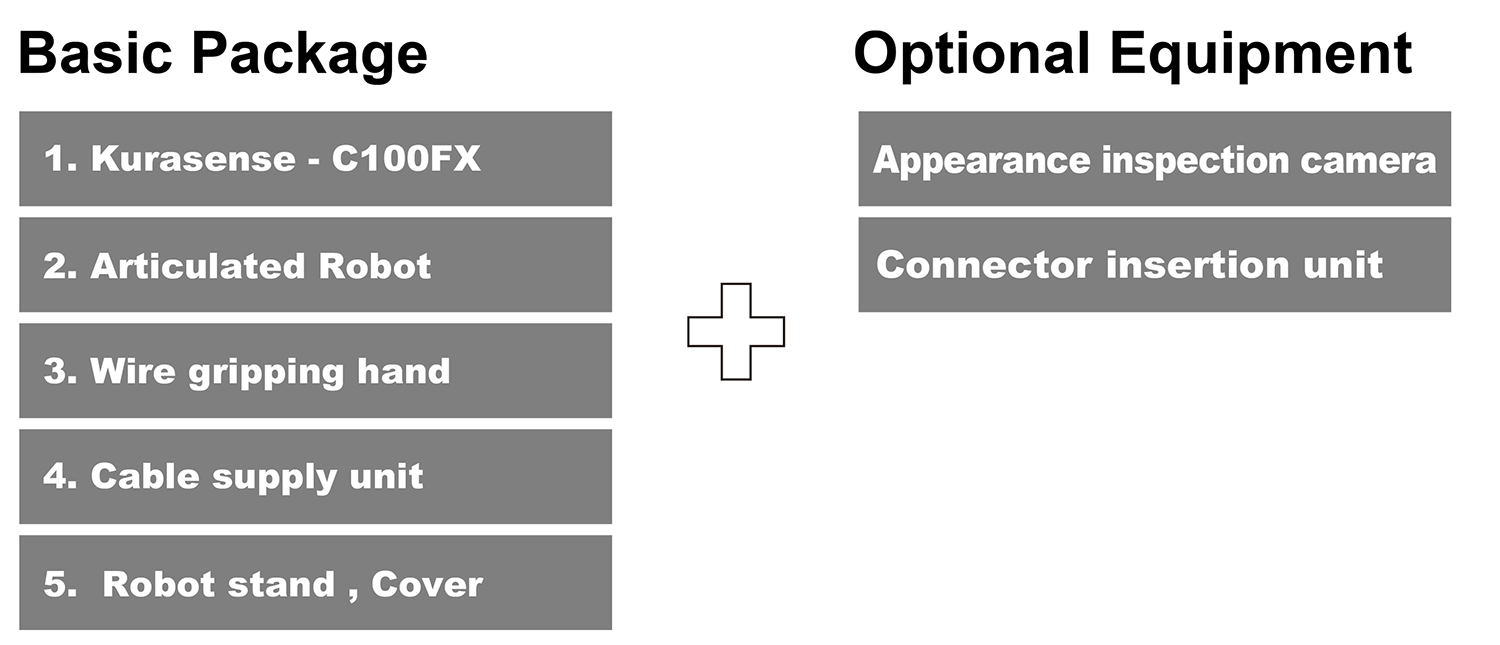

Basic package configuration

The wire harness manufacturing robot package includes: 1) 1 "Kurasense-C100", 2) 1 industrial vertical articulated robot, 3) 1 cable robot hand "Kurabotte", 4) 1 cable supply unit, 5) robot mount. The basic package includes safety fences, etc. (one set).

As options, we can offer terminal crimping, soldering, resistance welding, cable appearance inspection, etc. according to customer requests.

The Sensor is compatible with vertical articulated robots from various robot manufacturers, so you can choose according to your needs.

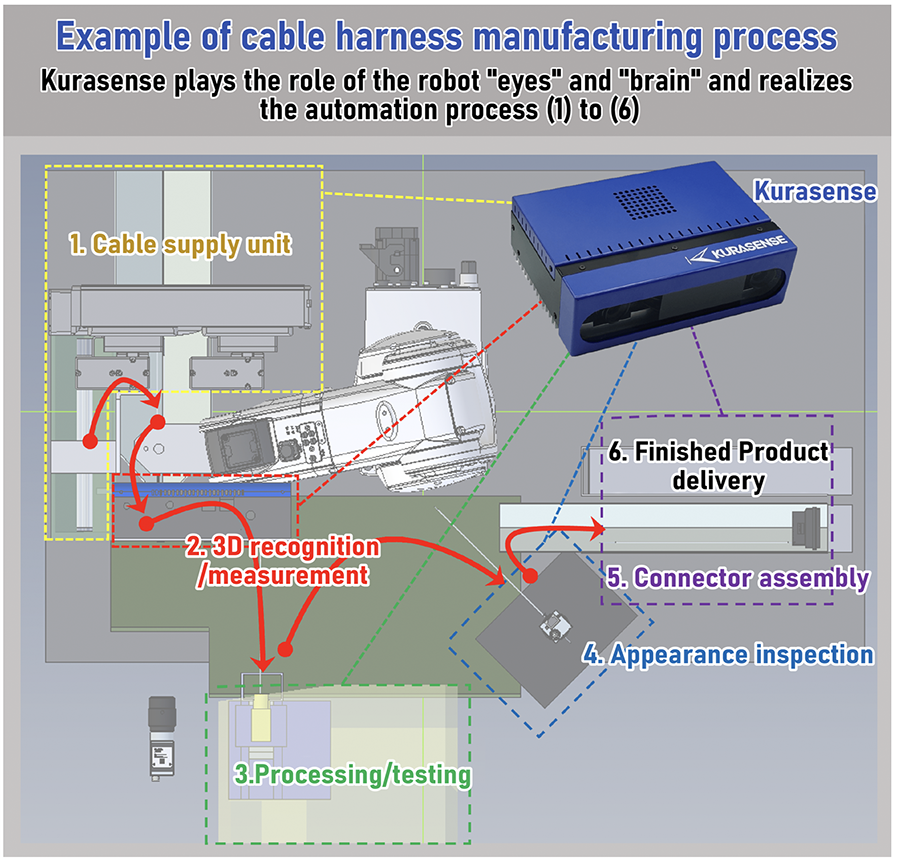

Harness manufacturing process (for terminal crimping and insertion into connectors)

①Cable supply (basic package)

One cable is automatically taken out from the preset cable bundle and the process starts.

②3D recognition/measurement (basic package)

Kurasense instantly measures and recognizes the direction of the tip of the cable when it is taken out. This allows the tip to be set accurately in the next process.

③Cable processing (optional)

The robot accurately sets the cable in the terminal crimping machine and crimp the terminal. Existing terminal crimping machines can be used. It is also possible to sell a new terminal crimping machine as a set.

④Appearance inspection (optional)

The processed cable is judged by an "exterior inspection camera unit" (optional item), and if it is determined to be defective, it is disposed of in the designated collection box in ⑥.

⑤Connector assembly (optional)

The crimped cable can be automatically inserted into the connector. You can select the connector supply method, such as a parts feeder.

⑥Finished product delivery (basic package)

If a product is determined to be defective during visual inspection or connector insertion, it will be disposed of in a designated collection box. Customization such as "shooter" and "Deliver to conveyor" is also possible.

In addition to the terminal crimping machine, resistance welding machines, characteristic testing machines, soldering machines, etc. can also be used for the cable processing process (optional) in ③.

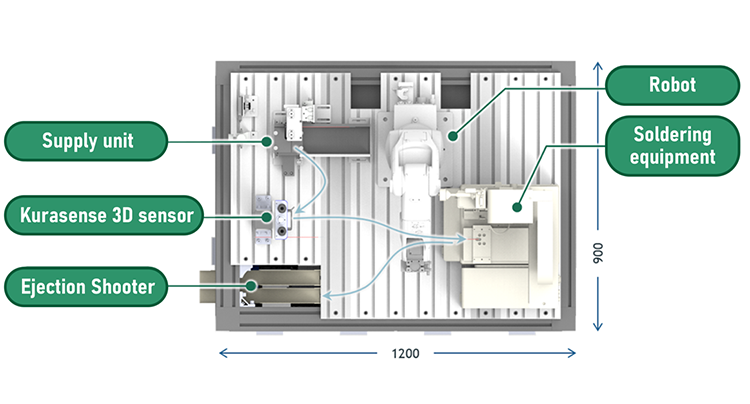

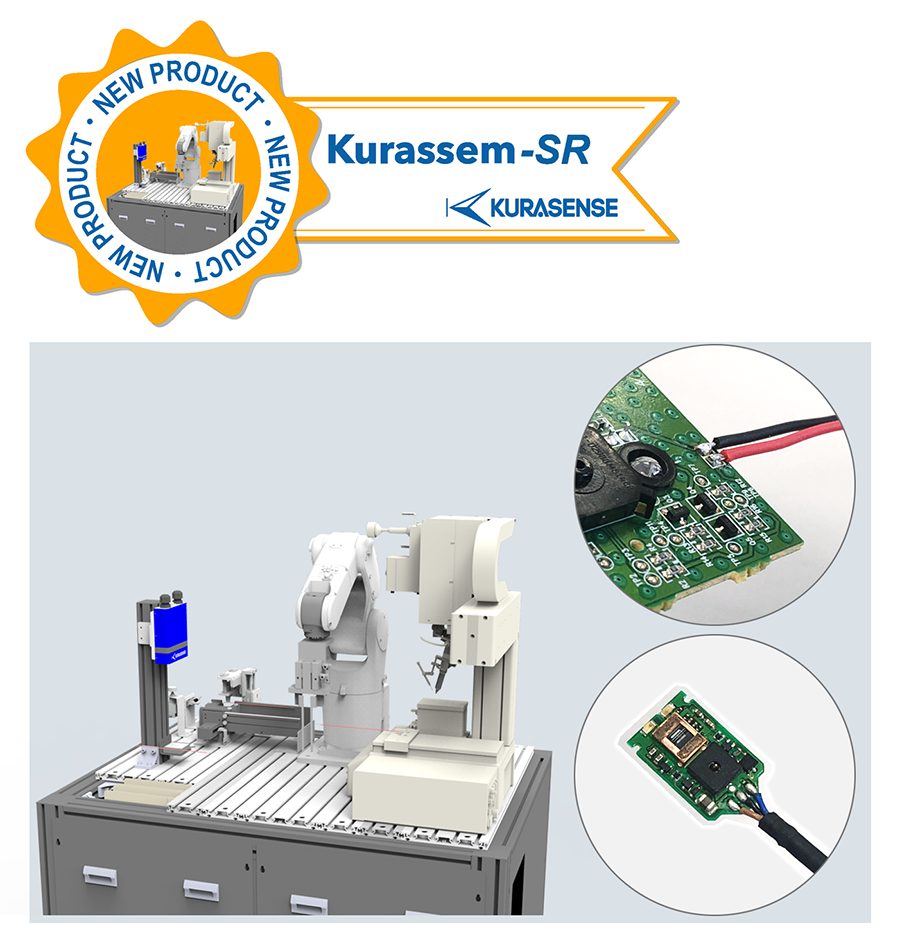

Automatic Lead Wire Soldering Robot Package

Lead wire automatic soldering robot package

Kurassem-SR

A robot positions the lead wires with high precision and automatically solders them.

Kurassem-SR is an automatic soldering robot package. Here bundles of lead wires are inserted as input. The robot picks the wire one by one from bundles does bend correction and then inserts them into position where soldering is done.

Application examples:

1. Sensor element:

It is possible to directly solder to the terminals of sensor elements or to crimp and solder the leads of resistors.

2. Electronic board:

It is possible to precisely position and solder leads to metal pads or through-holes on circuit boards.

3. Wire harness:

The complex soldering connections at the ends of harness connectors can be automated.

- Compatible work

- Electric wires, lead wires, etc.

- Robot

-

- 6-axis vertically articulated robot

- *Compatible wide range of robot manufacturer

- 3D sensor

- Made by Kurabo Kurasense - C100FX

- Equipment size

- 900(W) x 1200(D) x 1800(H) mm

- Utility

-

- Power supply

- 3 phase AC200V 30A 50Hz/60Hz

- Air

- 0.4MPa

- Target work

- Soldering, resistance welding, etc.

Basic package configuration

The lead wire automatic soldering robot package includes: (1) 1 "Kurasense-C100FX", 2) 1 industrial 6-axis vertical articulated robot, 3) 1 soldering equipment,

4) Supply unit, 5) Ejection shooter, 6) Robot stand, safety fence. etc. (set) are configured as a basic package.

It is compatible with robots from various robot manufacturers, so you can choose according to your needs.