Measuring and visualizing

technologies

-

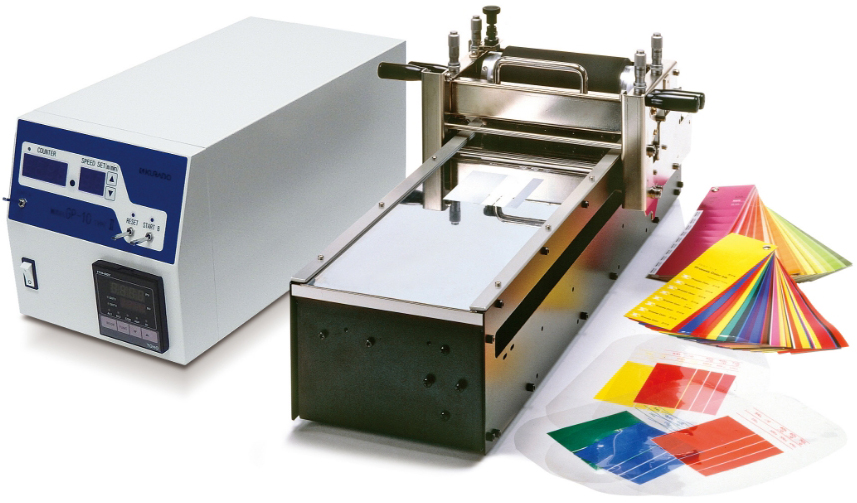

- Gravure coating tester

GP-10 TYPEⅡ -

- Features

- It produces coating samples with a small amount of coating agent and simple operations, so it can be used by raw material suppliers and film manufacturers as a test coating machine during research and development.

- Coating test

- Department in charge :

Advanced Technology Division

(Electronics)

- Gravure coating tester

-

- Chemical concentration meter

ChemicAlyzer -

- Features

- Using infrared measurement technology, it accurately measures a concentration level of a chemical solution used in cleaning and etching processes for production of semiconductors and liquid crystal panels.

- Infrared technologies

- Department in charge :

Advanced Technology Division

(Electronics)

- Chemical concentration meter

-

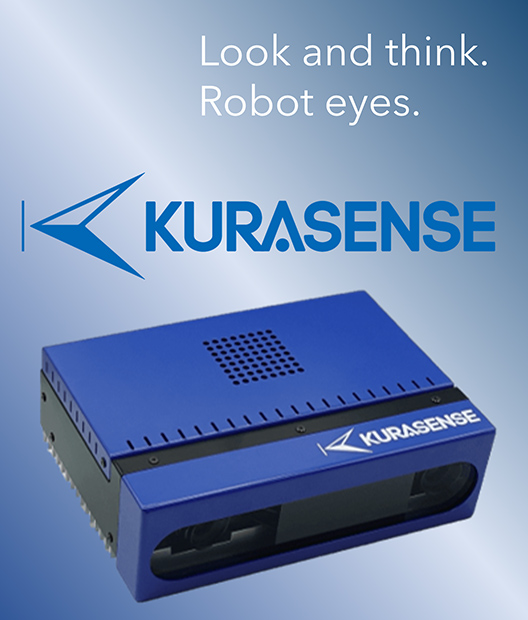

- KURASENSE

Robotic system

for electronic device assembly -

- Features

- Combining Kurabo’s exclusive high-speed image processing and 3D measurement technologies, “Kurasense-C100” provides 3D measurement and automatic fitting of a connector on the board of an electronic device, etc.

- Image processing technology

- Department in charge :

Advanced Technology Division

(Electronics)

- KURASENSE

-

- Film thickness meter

using infrared absorption

RX Series -

- Features

- Using infrared measurement technology, it measures film thickness, coating thickness on different types of substrates, and moisture of polarizers with high precision.

- Infrared technologies

- Department in charge :

Advanced Technology Division

(Electronics)

- Film thickness meter

-

- Visual inspection systems

for boards

BBMaster -

- Features

- Utilizing Kurabo’s proprietary lighting and image processing technologies, it detects defects such as minute scratches, dirt and dents on printed circuit boards with high precision.

- Image processing technology

- Department in charge :

Advanced Technology Division

(Electronics)

- Visual inspection systems

Weighing and mixing technologies

-

- Planetary-style

mixing and defoaming device

MAZERUSTAR -

- Features

- By continually revolving and rotating the container filled with materials, mixing and defoaming can be achieved simultaneously without using stirring rods, blades or vacuum extractors.

- Mixing and defoaming technology

- Department in charge :

Advanced Technology Division

(Bio-Medical Products)

- Planetary-style

Wastewater treatment technologies

-

- Device to feed chemical solutions

-

- Features

- We design and construct facilities for preparing and filling high-purity chemical solutions, using an exclusively developed fluororesin filter and other technologies, facilities for storing and supplying chemical solutions, and dust-free and sterile clean rooms.

- Technology of chemical

feed systems - Department in charge :

Advanced Technology Division

(Engineering)

Resin preparation technologiesExtrusion and molding technologies

-

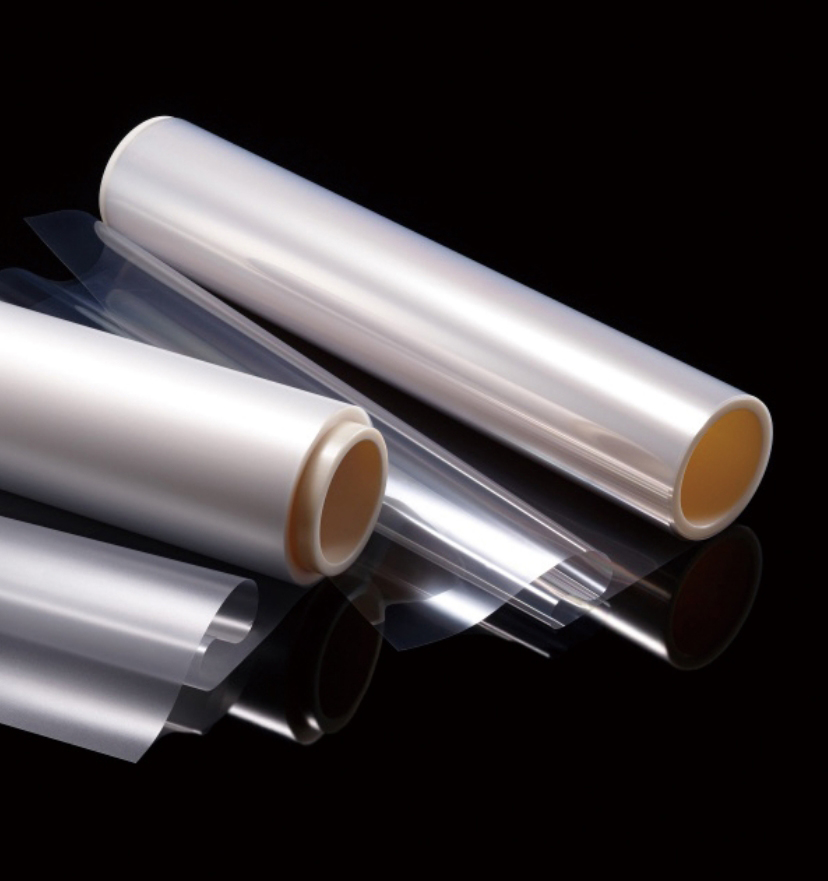

- High heat resistance +

High transparency PEEK film

EXPEEK -

- Features

- This film hardly changes its dimensions even in a high-temperature environment and has excellent transparency. The total light transmittance is 83%, and it transmits UV rays above 370 nm. It can have an adhesive put on it and used as a semiconductor tape, etc.

- Technology to form

special plastic films - Department in charge :

Chemical Products Division - Heat-resistant polystyrene film

Oidys -

- Features

- This polystyrene film has improved heat resistance and can be used even in a high-temperature process of about 200 degrees C. It has been already used for releasing molds by taking advantage of its surface features of low polarity and wetting tension, and its application for 5G boards is also being developed using its low dielectric properties.

- Technology to form

special plastic films - Department in charge :

Chemical Products Division

- High heat resistance +

-

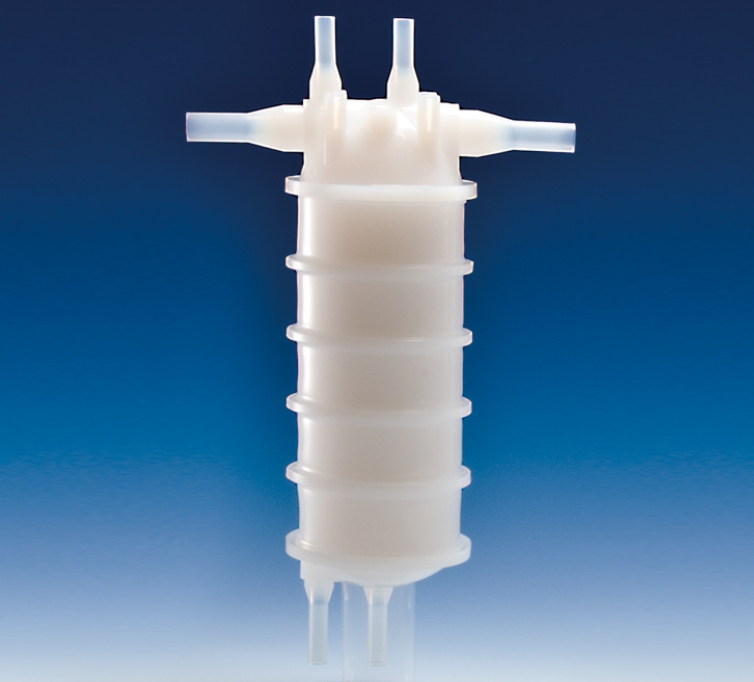

- 100% fluororesin filter

KRANFIL -

- Features

- Made of 100% fluororesin, it has excellent resistance to chemicals and heat, with almost no metal elution during use. The model with the vented secondary side removes air from the secondary side when used upside down.

- Filter production technology

- Department in charge :

Chemical Products Division

- 100% fluororesin filter

Textile technologies

-

IEC-compliant material for work clothes: Elearth-

- Features

- Made of cotton and polyester, Elearth is the first in the textile industry to comply with the international standard IEC 61340-5-1 (hereinafter referred to as the “IEC standard”) for protecting electronic devices from electrostatic discharge.

This material for working clothes is designed for comfort and to protect electronic devices from electrostatic discharge.

- Functional fibers

- Department in charge :

Textile Business Division

-

Supports working postures

CBW(CONDITIONING BRACE WEAR)-

- Features

- “CBW” is support wear combined with work pants and designed to reduce the worker’s load.This new stylish support wear can be worn all day long for greater mobility and reduces lower back stress during work.

- Functional fibers

- Department in charge :

Textile Business Division